In the ever-evolving field of 3D CAD design, efficiency is not just an added value but a necessity. Designers facing tight deadlines and increasingly complex projects need tools to streamline their workflows. Small gains in daily efficiency can accumulate into significant productivity improvements in today’s competitive market.

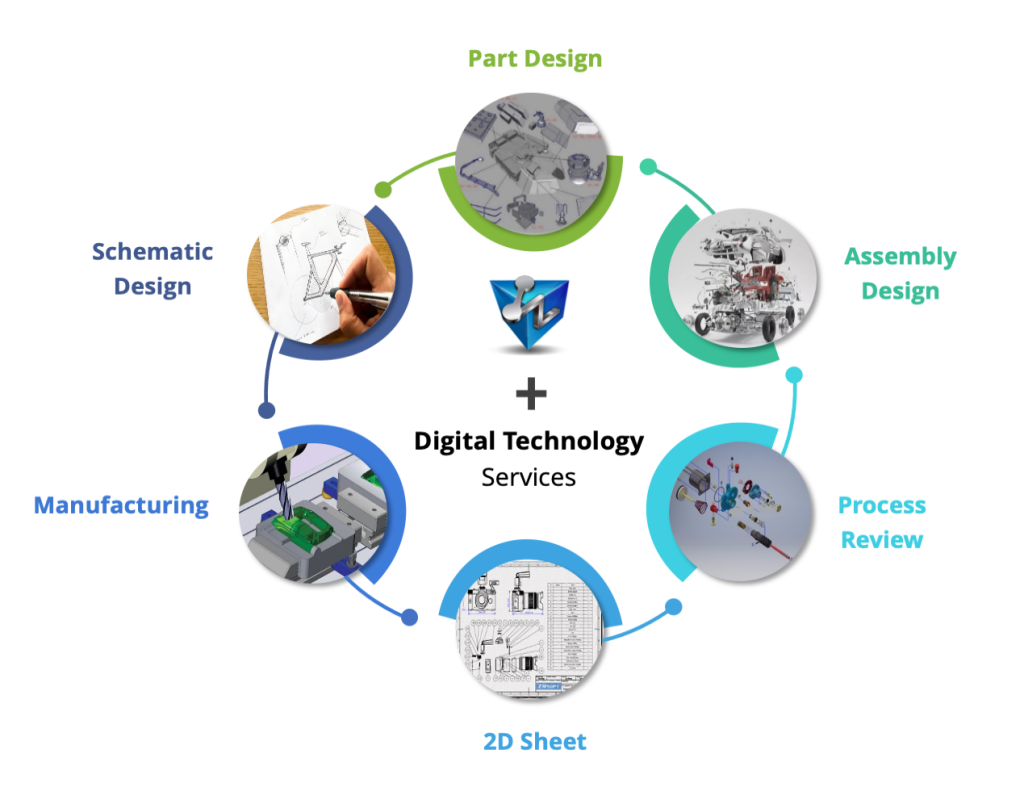

Each iteration of ZW3D is developed with efficiency at its core, aiming to empower designers and engineers to work smarter. ZW3D keeps optimizing the product development process, enabling the professionals to focus on high-value activities and allowing the system to handle repetitive, routine, and time-consuming tasks. In addition, by decreasing potential manual errors through automation, ZW3D ensures better accuracy and consistency.

Real-World Challenges in 3D Design

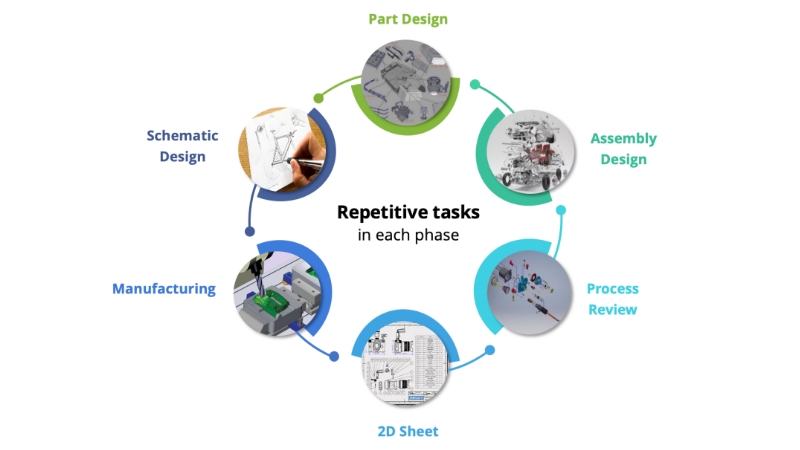

From schematic design to manufacturing, boosting efficiency is an ongoing challenge that differs across industries. Clients producing serialized products, for example, need to cut down on repetitive design tasks to save time and resources. On the other hand, those in mature and highly competitive markets must speed up their design and quotation processes to win more orders and stay ahead of the competition.

Repetitive Tasks – Up to 90%

Manual Reviews – 5 Engineers 2 Days to Complete

BOM Conversion – 2 to 3 Days

Achieve More in Less Time with ZW3D

1. Product Modular Design – Enhance Model Reusability

Efficiency Gain: Reduces design time by 30%.

ZW3D enhances efficiency in parts and assembly design through configuration-based modular design. For example, in the clamping unit assembly of an injection molding machine, the platen (mold fixing plate) must be adjusted for different mold types using T-slots. By defining key product configurations, ZW3D provides a solution tailored to customer needs. Depending on different application scenarios, users can switch directly to different configurations, enhancing the model’s reusability and significantly reducing model redesign time by 30%.

This approach minimizes repetitive work and ensures that designers can quickly adapt to various design requirements without starting from scratch.

2. Part Series Design – Reduce Repetitive Drawing & Manual Annotation

Efficiency Gain: Reduces design time by 90%.

In serialized product design, such as flat screens, the overall structural arrangement often remains the same, but variations in external dimensions require new sets of models and drawings. In response to this scenario, ZW3D has developed parametric templates tailored to the key parameters of customers’ flat screen designs. By modifying these parameters, new models can be quickly generated.

Moreover, ZW3D includes a function that automatically annotates views according to the engineering drawing templates and labeling requirements of the customer’s serialized products. This automation significantly reduces the manual drawing process, cutting down design time by 90%, standardizing the style of the customer’s drawings, and enhancing consistency.

3. Process Review – Automatic Check to Minimize Manual Inspection

Efficiency Gain: Reduces workload by 1-2 days and identifies 95% of design issues.

Process review is an indispensable part of design production. It is also prone to repetitive tasks, such as checking the alignment of holes during assembly, verifying that hole sizes match bolt dimensions, and ensuring the spacing between holes meets specifications. The number of hole fittings to inspect in equipment design can be extensive, typically requiring five engineers two days to complete.

ZW3D addresses this by developing an automated review function tailored to the company’s specific process review criteria. This function automatically flags discrepancies, facilitating item-by-item troubleshooting. For example, during an assembly check, the automated function can instantly highlight misaligned holes or incorrect dimensions, allowing engineers to quickly address these issues without manually inspecting each component and ultimately enabling faster and more accurate reviews.

4. BOM Conversion – Quick & Correct in One-Click

Efficiency Gain: Reduces workload by 2-3 days.

ZW3D has developed a feature for quickly setting part attributes during the part design stage based on the customer’s workflow and requirements. Customers complete these settings during the design process and, with a single click, can export the MBOM.

This integrated method disperses what might have been a 2-3 day task across various stages of part design, greatly enhancing efficiency and process continuity. It speeds up the BOM conversion and reduces potential errors and repetitive work, making the entire design-to-production process more seamless.

5. Product Classification – Rapic Processing & Accurate Procurement List

Efficiency Gain: Improves design efficiency by 10%.

In addition to the feature of setting part attributes, ZW3D and its channel partners offer customized services for quickly categorizing BOMs. Using the part comparison function, ZW3D swiftly categorizes parts and outputs corresponding processing or procurement lists based on the classification results.

This enhances efficiency by 10%, streamlining the design process and ensuring accurate part management. The part comparison technology matched part lists, and comprehensive part library collectively contributes to a more efficient workflow and better resource management.

6. CAM Processing – Faster Production with Less Manual Efforts

Efficiency Gain: Reduces workload from 4 hours to 2 hours, improving manufacturing efficiency by 50%.

In CAM processing, ZW3D provides customers with customized rapid machining solutions. These include quickly establishing machining coordinate systems, rapidly generating milling operations based on profile recognition, swiftly creating drilling operations based on geometric recognition and a one-click function to generate workshop program sheets.

These features streamline the CAM processing workflow, significantly reducing the workload from 4 to 2 hours. By automating key tasks, ZW3D ensures a more efficient and effective manufacturing process, allowing faster production and reduced manual effort.

7. Digital Platform – Rapid Design and Quotation

Efficiency Gain: Reduces workload from 3 days to 0.5 days.

ZW3D offers a digital platform tailored to custom requirements, facilitating rapid design and quoting. Once a customer receives an order, they need only input the order’s parameter requirements from an Excel sheet into ZW3D. This generates a parametric model directly and completes drawing projection and annotation with a single click, ultimately exporting the BOM and quotation sheet.

Conclusion

ZW3D is more than just a 3D CAD product; it provides a comprehensive suite of digital technology and services tailored to enhance design efficiency. By addressing specific client requirements and eliminating repetitive tasks, ZW3D allows engineers to focus on innovation and deliver high-quality designs faster.

With an average improvement of 30% in design efficiency, ZW3D is a powerful tool for any design team looking to stay competitive in today’s fast-paced market. By leveraging ZW3D’s advanced features and customized solutions, businesses can significantly enhance their design workflows, reduce time-to-market, and maintain a competitive edge.

.png)