3D printing technology, also known as additive manufacturing, is a process that creates three-dimensional objects by adding material layer by layer. Through 3D printing STL files, you can transform the complex structures imagined in your mind into tangible realities.

As technology advances, 3D printing materials are no longer limited to plastics and resins. Metal materials, such as aluminum, are gaining increasing attention due to their lightweight and high strength, making them ideal for aerospace, automotive manufacturing, and other industries.

In this article, we will provide you with a comprehensive guide to exploring all aspects of aluminum 3D printing, including its advantages, applications, and technical details. Hopefully, by the end of this article, you will be better equipped to start your 3D printing projects and create unique and exquisite pieces. Now, let’s get started.

What Is 3D Printing Aluminum? What Are the Main Applications?

Aluminum is a robust metal with excellent mechanical properties, corrosion resistance, and lightweight characteristics, making it one of the most popular metals in industrial manufacturing. 3D printing aluminum is an additive manufacturing process that involves adding layers of aluminum powder or aluminum alloy powder, which are then melted and solidified using a laser or electron beam.

This technology leverages the properties of aluminum to produce complex and high-performance metal parts. Nowadays, aluminum 3D printing is widely used in various industries, such as:

- Aerospace: Manufacturing lightweight, high-strength, complex components like aircraft structural parts and turbine blades to improve fuel efficiency and performance of aircraft.

- Automotive Manufacturing: Producing high-performance engine components, radiators, and structural parts to enhance vehicle performance and quality.

- Medical Devices: Creating customized implants, surgical tools, and prosthetics that offer better adaptability and functionality.

- Electronics: Fabricating lightweight and durable housings and structural components for devices like laptops and smartphones.

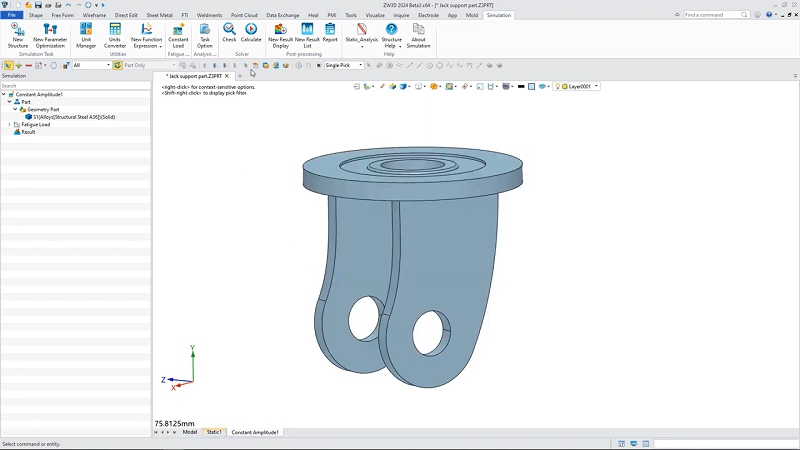

To achieve the printing of aluminum objects, it is usually necessary to model in professional 3D modeling software like ZW3D. By using such software, designers can create precise 3D models and convert them into the STL file format required for 3D printing, ensuring accuracy and efficiency in the printing process.

| Note: ZWSOFT recently launched ZW3D 2025, a new version of the best 3D modeling software. This latest release not only meets the professional modeling needs of engineers but also offers a one-time purchase option, making it the best solution for those who require long-term use of modeling software. If you’re interested, you can download it for a 30-day free trial. |

Benefits of Aluminum 3D Printing

As mentioned earlier, aluminum is one of the most popular metals in industrial production and is widely used in many fields due to its rich properties. In this section, we’ll delve into the unique benefits of aluminum 3D printing compared to traditional manufacturing methods.

1. Weight Reduction

The low density of aluminum makes the printed components very lightweight, which is particularly beneficial in applications requiring weight reduction, such as the aerospace industry. Reducing the weight of structural components can decrease fuel consumption, increase payload capacity, and enhance overall performance and efficiency.

2. Flexible Design and Production

3D printing aluminum casting allows for the creation of parts with complex geometries and internal structures, such as honeycomb structures and intricate curved designs, which are difficult to achieve with traditional manufacturing methods. This flexibility enables designers to tailor parts to specific requirements, meeting the unique demands of different applications, such as medical implants and high-performance mechanical components.

3. High Strength and Durability

Despite being lightweight, aluminum possesses high strength and rigidity, capable of withstanding various mechanical stresses. This makes aluminum 3D printed parts ideal for applications requiring high strength and durability, such as engine components and industrial machinery parts. The high strength characteristics of aluminum ensure the reliability and stability of parts under demanding conditions.

4. Cost Reduction

The core principle of aluminum 3D printing is layer-by-layer material addition, which can reduce overall production costs by minimizing material waste and reducing the need for tools and moulds. Additionally, aluminum’s natural corrosion resistance makes it suitable for use in harsh environments, extending the lifespan of parts and reducing maintenance and replacement costs.

5. Short Development Cycle

Compared to traditional mould manufacturing, especially for complex-shaped parts, aluminum 3D printing can produce finished products within hours to days, significantly speeding up the product development cycle.

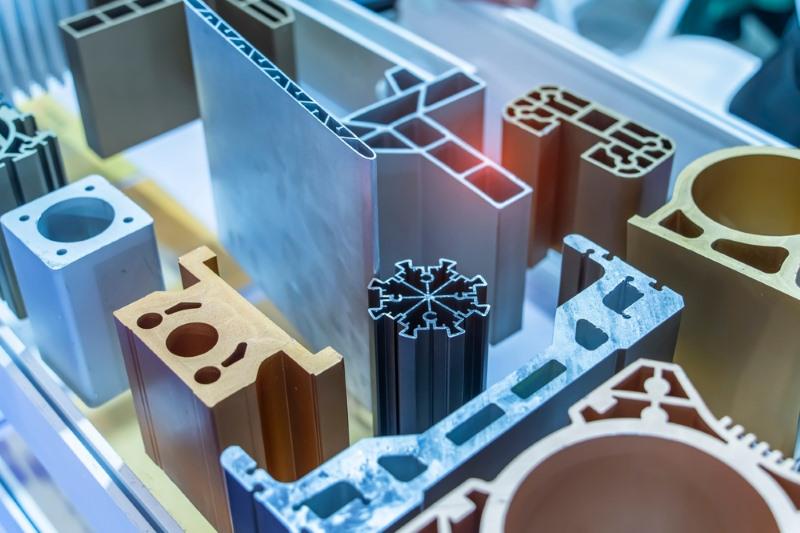

Understanding Aluminum Materials

In aluminum 3D printing, the selection and use of materials are crucial as they directly impact the quality and performance of the printed parts. To help you better understand aluminum materials, we have summarized some common options along with their characteristics and application examples in the table below.

| Aluminum Materials | Characteristics | Applications |

| Pure Aluminum |

|

Commonly used in applications requiring high thermal and electrical conductivity, such as electronic products and heat sinks. |

| Aluminum Alloys | Aluminum alloys are metal materials that enhance the properties of aluminum by adding other elements (such as silicon, magnesium, copper, zinc, etc.). | |

| AlSi10Mg

|

|

Airbus uses AlSi10Mg for A320 aircraft flap brackets; Audi uses AlSi10Mg for engine part prototyping and small batch production. |

| AlSi12 |

|

Ford uses AlSi12 for manufacturing engine components such as pistons and cylinder heads. |

| AlSi7Mg0.5 |

|

Volkswagen uses AlSi7Mg0.5 for engine components and transmission systems. |

| Al7075 |

|

Boeing uses Al7075 for aircraft wings and fuselage structures; Canyon Bicycles uses Al7075 for high-performance bicycle frames. |

| Al6061 |

|

Apple uses Al6061 for laptop casings; Tesla uses Al6061 in the chassis and body structure of electric vehicles. |

| Scalmalloy |

|

SpaceX uses Scalmalloy for rocket parts and satellite components. |

We can see that each material has unique properties, such as good strength or low density. Therefore, when choosing 3D printing aluminum materials, you need to consider your specific application needs.

For instance, in the aerospace sector, high-strength, lightweight aluminum alloys are typically chosen, whereas, in electronic products, pure aluminum with good thermal conductivity may be preferred.

Additionally, factors such as material strength, hardness, ductility, and other mechanical properties must be taken into account to ensure the printed parts can withstand the stresses and loads in actual use.

What Is the Most Common Technology for Aluminum 3D Printing?

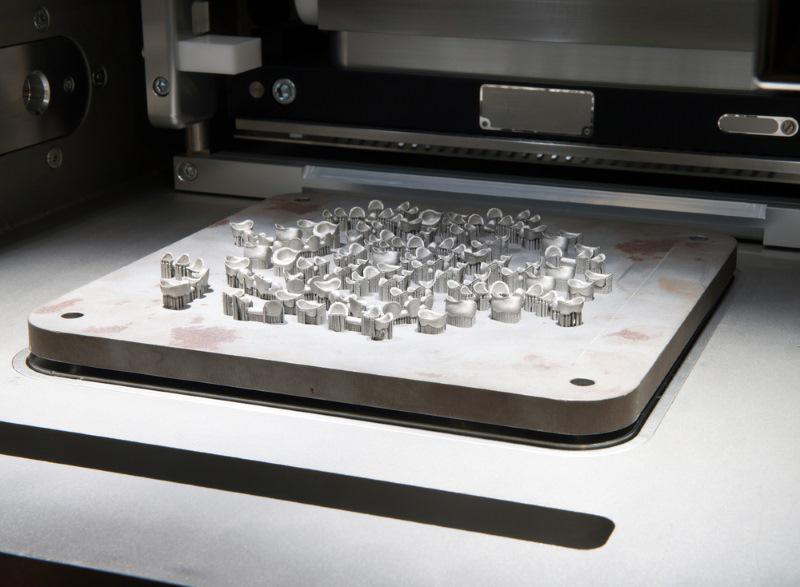

SLM and DMLS. In aluminum 3D printing, there are several different technologies to choose from, each with its unique advantages and applications. Common aluminum 3D printing technologies include:

- Selective Laser Melting (SLM): Use a high-power laser to fully melt and fuse metal powder layer by layer.

- Direct Metal Laser Sintering (DMLS): Use a laser to sinter metal powder particles together layer by layer.

- Electron Beam Melting (EBM): Uses an electron beam to melt metal powder, forming dense metal parts.

- Binder Jetting: Use spraying a binder onto powder material layer by layer to form a part, followed by post-processing to enhance strength and stability.

- Directed Energy Deposition (DED): Use feeding metal powder or wire into a high-energy beam (such as a laser or electron beam) to melt it, then depositing it onto a substrate layer by layer to build parts.

Among these, the most commonly used technology is laser powder bed fusion, which includes SLM and DMLS.

SLM is a powder bed-based additive manufacturing technology. It creates complex parts by using a high-power laser to melt metal powder layer by layer. This technology can get 3D aluminum designs printed on a 3D printer with high precision because it produces parts with high density and material properties similar to forged parts.

DMLS is similar to SLM and is also a laser-based metal 3D printing technology. However, DMLS uses a laser to locally sinter metal powder together rather than fully melting it. DMLS can handle a variety of metal materials and is suitable for manufacturing parts with complex geometries. Due to its local sintering approach, DMLS is typically faster than SLM, making it more suitable for quickly manufacturing complex parts and prototypes.

FAQs About 3D Printing Aluminum

Is There an Aluminum 3D Printing Service?

Yes, Xometry is a leading on-demand manufacturing service provider that offers a variety of manufacturing solutions, including 3D print aluminum. Xometry’s aluminum 3D printing service provides multiple material options, such as AlSi10Mg, AlSi12, Al7075, and various 3D printing technologies, including SLM and DMLS, ensuring that the manufactured aluminum parts have high precision and high strength.

Xometry’s online platform allows users to upload their design files, such as STEP, STL, DXF, etc. Once you select the production method and material, the platform automatically generates a quote and provides manufacturing recommendations. All U.S. orders come with free shipping.

Does the Aluminum Used in 3D Printing Differ from Regular Metalworking?

While 3D printing aluminum and conventionally machined aluminum share similarities in base materials, there are significant differences in terms of material optimization, processing methods, and application areas.

3D printing aluminum typically uses high-purity aluminum alloy powders with lower impurity levels. As a result, the printed parts exhibit enhanced strength, toughness, and corrosion resistance. Due to these improved properties, 3D-printed aluminum is often used for manufacturing small batches of complex parts, such as aerospace components and medical devices.

In contrast, aluminum used in traditional metalworking often has lower purity, resulting in relatively lower performance. Therefore, it is primarily used for producing large quantities of simple-shaped parts, such as automotive components and can packaging.

Conclusion

3D printing aluminum technology is rapidly evolving and has become an important tool. It not only transforms the manufacturing process but also drives innovation in product design and manufacturing efficiency across various industries, offering greater design freedom and performance advantages.

In this article, we have provided a comprehensive introduction to aluminum 3D printing. If you are a beginner, this guide should give you a basic understanding of 3D printing aluminum and help you get started on your projects.

.png)